In today’s fast-evolving industrial landscape, automation is no longer optional—it’s essential. At the heart of modern automation systems lies the Programmable Logic Controller (PLC). From manufacturing plants to process industries, PLCs play a critical role in improving efficiency, accuracy, and reliability.

In this blog, we’ll explain what a PLC is, how it works, its applications, and why choosing the right PLC matters for your business.

What Is a PLC (Programmable Logic Controller)?

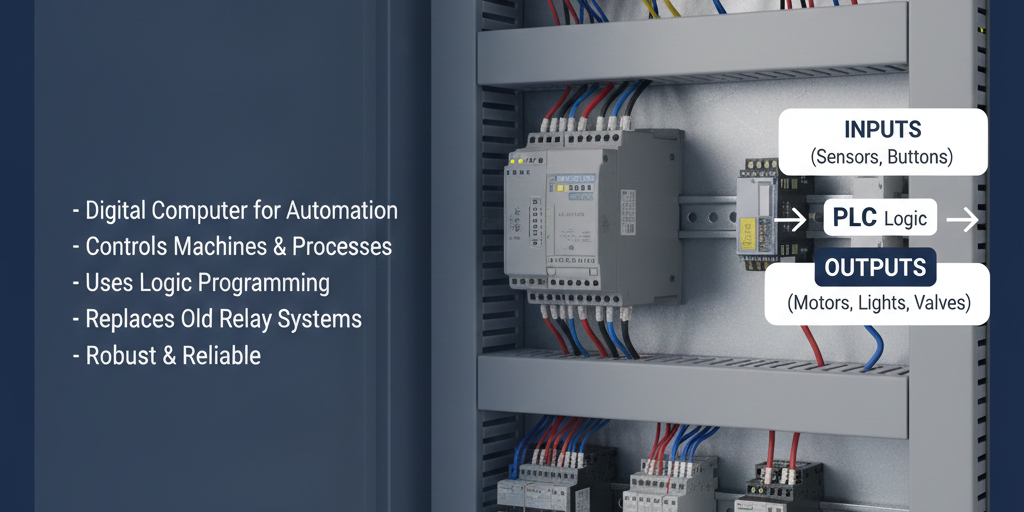

A Programmable Logic Controller (PLC) is a rugged industrial computer designed to control machines, processes, and production lines. Unlike regular computers, PLCs are built to operate reliably in harsh environments involving dust, heat, vibration, and electrical noise.

PLCs continuously monitor input signals (such as sensors and switches), process them using a programmed logic, and control outputs (like motors, valves, and relays).

Key Components of a PLC System

A typical PLC system consists of:

- CPU (Central Processing Unit): Executes control logic

- Input Modules: Receive signals from sensors and switches

- Output Modules: Control actuators, motors, and devices

- Power Supply: Provides required electrical power

- Communication Modules: Enable data exchange with HMIs, SCADA, and networks

How Does a PLC Work?

The PLC operates in a continuous loop known as the scan cycle:

- Read Inputs – Collects data from sensors and field devices

- Execute Program – Processes logic based on programmed instructions

- Update Outputs – Activates or deactivates output devices

This fast and repetitive cycle ensures real-time control and precise automation.

Applications of PLCs in Industry

PLCs are widely used across multiple industries, including:

- Manufacturing & Assembly Lines

- Packaging Machines

- Water & Wastewater Treatment Plants

- Power Plants

- Oil & Gas Industries

- Textile, Food & Beverage, and Pharma Industries

Their flexibility allows them to control both simple and highly complex automation systems.

Advantages of Using PLCs

Choosing PLC-based automation offers several benefits:

- High Reliability & Durability

- Easy Programming & Troubleshooting

- Reduced Wiring Compared to Relay Systems

- Scalability for Future Expansion

- Improved Productivity & Safety

These advantages make PLCs a long-term and cost-effective automation solution.

PLC vs Traditional Relay Control

Compared to conventional relay-based control panels, PLCs offer:

- Faster response time

- Compact system design

- Easy modifications without rewiring

- Advanced diagnostics and monitoring

This is why PLCs have largely replaced relay logic in modern industries.

Choosing the Right PLC for Your Application

Selecting the right PLC depends on factors such as:

- Number of inputs and outputs

- Type of application (simple or complex)

- Communication requirements

- Expansion capability

- Brand compatibility and support

Working with an experienced automation partner ensures you get the right PLC solution tailored to your needs.

PLC Solutions by Avnika Electrosystems

At Avnika Electrosystems, we provide reliable PLC solutions, HMIs, VFDs, sensors, and industrial automation components to meet diverse industry requirements. Our expertise helps businesses improve operational efficiency while ensuring long-term performance and scalability.

Conclusion

PLCs are the backbone of industrial automation, offering unmatched control, reliability, and flexibility. Whether you’re upgrading an existing system or building a new automation setup, investing in the right PLC solution is a smart move toward operational excellence.

If you’re looking for expert guidance or quality automation components, Avnika Electrosystems is here to support your automation journey.